4 deposits of £10, £20, £50, £100 matched with a bonus cash offer of same value (14 day expiry). Uniform coating thickness throughout patch.

Coating Windows Of A Slot Coating Process In The Plane Of Vacuum Pvac Download Scientific Diagram

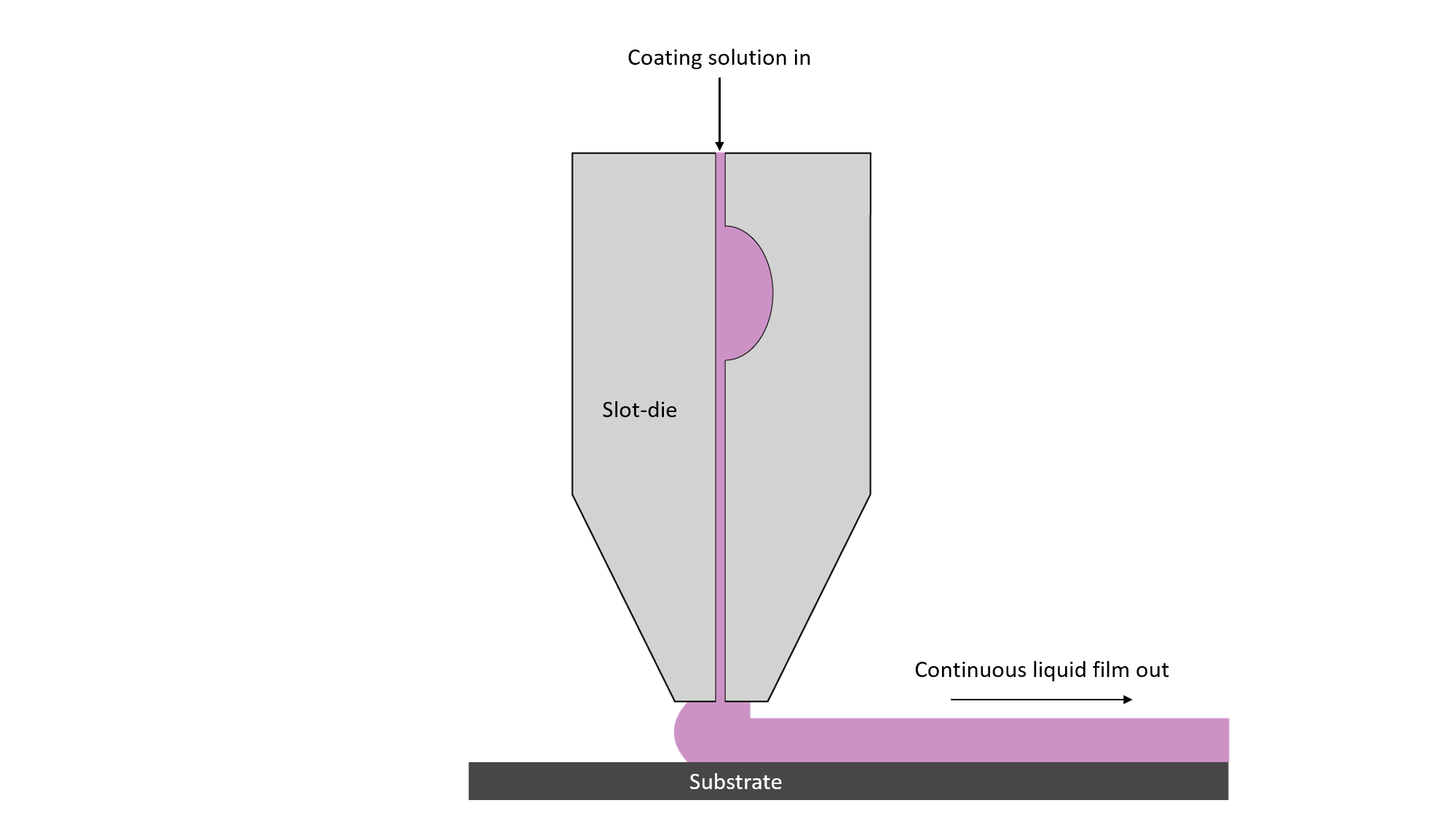

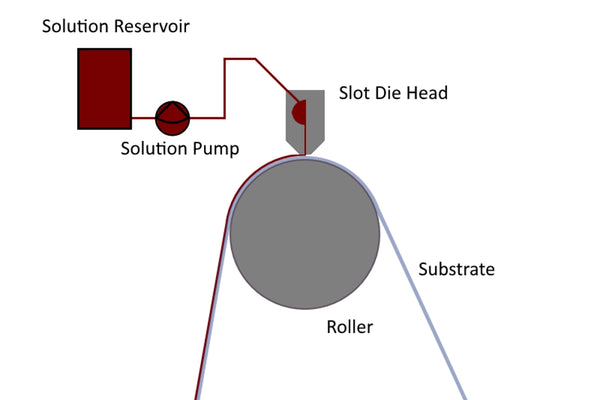

Dispensing it at a controlled rate.

Slot die coating thickness. Intermittent slot die coating is widely used to create the structured coating layer in the flexible electronics production but is inevitable to engender trailing edge of uneven coating thickness. The experimental procedure for the determination of the minimum wet thickness for a given coating solution was the same as reported previously.briefly, a coating solution was prepared and then fed into the slot die at a constant flow rate q.the coating (roller) speed v was slowly adjusted by means of a regulator (f) to increase from zero, where dripping was first observed, to a speed high. 18+ new eligible uk players only.

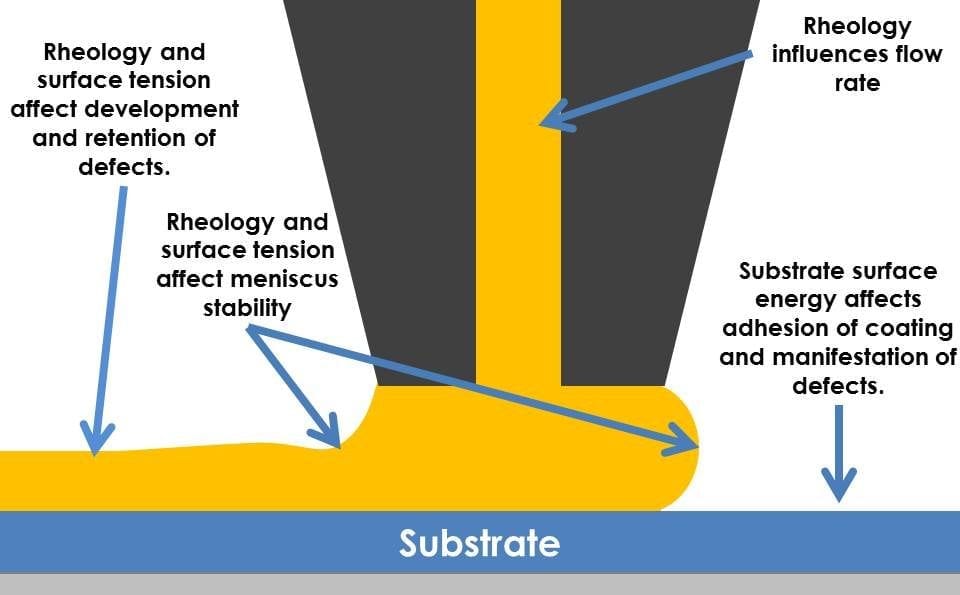

35x real money cash wagering (within 30 days) on eligible games before bonus cash is credited. 4, 5 traditionally, slot die coating has. A viscoelastic coating can store energy from the high stresses experienced during extrusion.

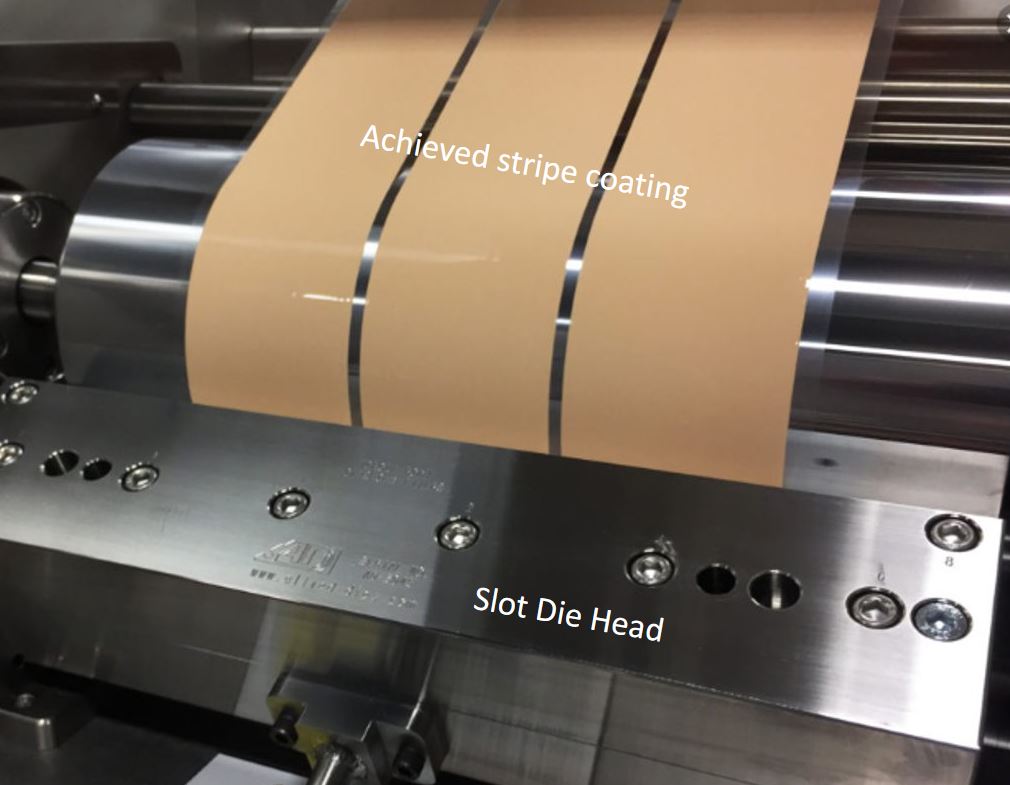

Slot die coating is a huge advantage for the right industries. The website is operated and managed by everymatrix ltd., a company slot die coating thickness control bearing registration number c44411, and having its registered address at level 5, suite 1a, portomaso business tower, vjal portomaso, st. In the past decade, slot die has become one of the most widely used coating methods in the world.

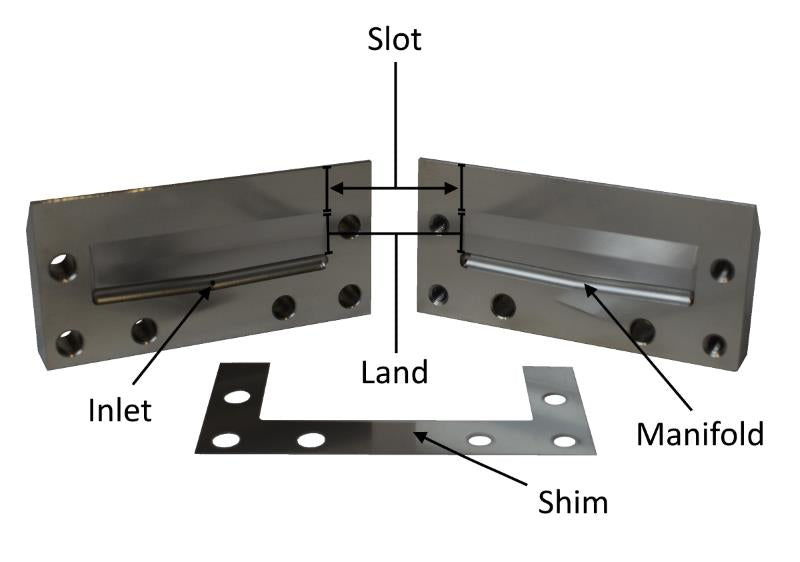

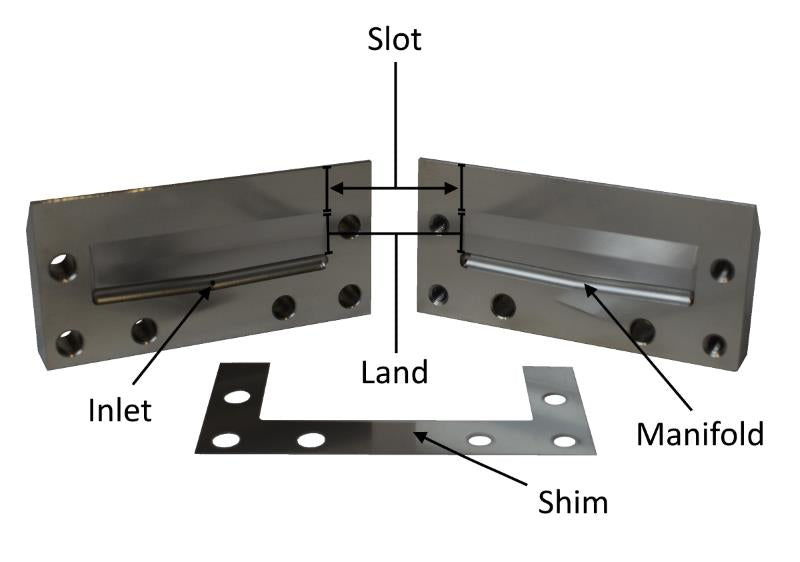

Background rheology • viscosity • shear rate (stress) o 1. This means that the wet film thickness is determined by the amount of solution placed onto the substrate. Background • slot die applications • viscosity versus shear rate • % solids • coating thickness • particle size • coating width • line speed • operating temperature 5.

Ultracoat™ v flexible lip slot dies. We can predict viscoelasticity by measuring normal stress generation during a shear rate sweep. Viscoelastic coatings swell as they exit the slot die, potentially resulting in destabilisation of the menisci and introducing a range of defects.

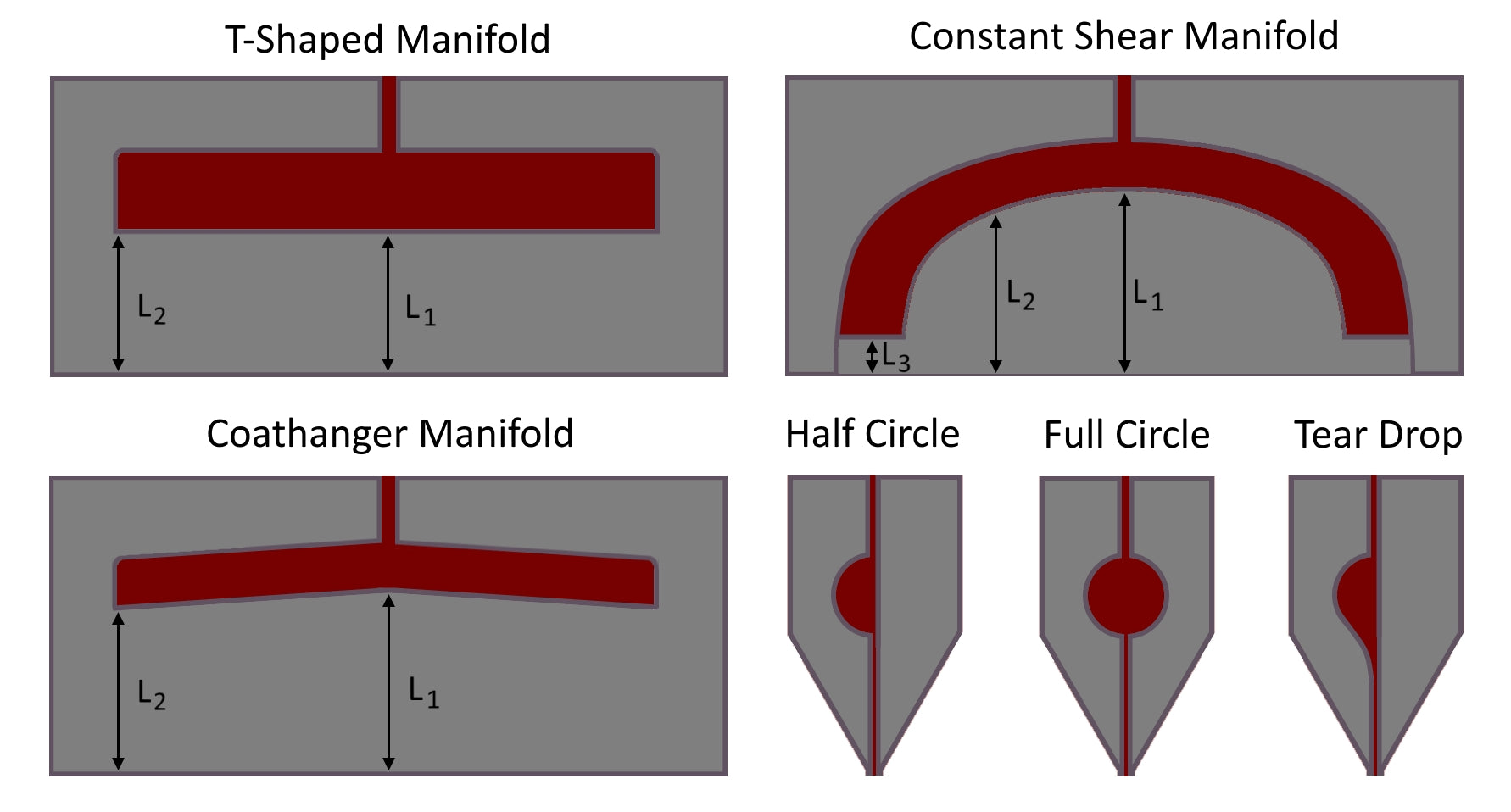

Here’s a graphic of a patch to illustrate some of the terms from above: Background • slot die design • rheology • manifold • body sections • fluid flow control 6. This is achieved by precisely metering the process fluid;

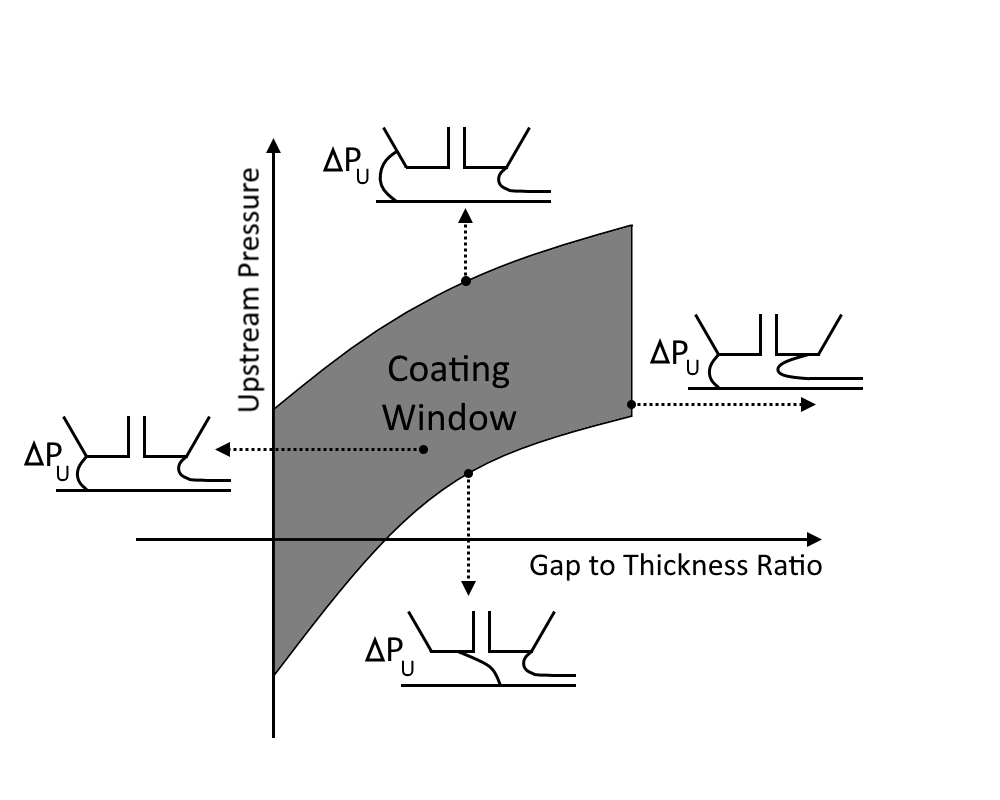

However, the liquid flow in the application region, so called the coating bead, is strongly affected by operating parameters, liquid properties, and design parameters; Julians, stj 4012, malta and by everymatrix n.v., a limited liability company incorporated under the laws of slot die coating thickness control curacao. As we noted earlier, industries such as electronics, medical devices and pharmaceutical keeping raising the bar.

Under £50 =10 spins, £50 slot die coating thickness. All other parameters work to improve the uniformity and stability of the coating. Fixed wet coating lip face

There exist three distinct coating regions (i, ii, and iii), depending.

Slot Die Coating A Coating Technology Thats Steadily Increasing Its Market Share In Advanced Technologies - Scifame

The Critical Variable Slot Die Lip Gap

Httpswwwfomtechnologiescomwp-contentuploads202008fom-technologies-faq_refpdf

Slot Die Coating Of Polybenzimiazole Based Membranes At The Air Engulfment Limit - Sciencedirect

Slot-die Coating Theory Design Applications Ossila

Slot-die Coating Theory Design Applications Ossila

Slot-die Coating Theory Design Applications Ossila

Slot-die Coating Theory Design Applications Ossila

Schematics Of The Slot-die Coater Download Scientific Diagram

Customized Flat Slot Die Coater Up To 1 W X 2 L Meter - Msk-dcp-s650

A Schematic Of Slot Die Coating B Schematic And C Photograph Of The Download Scientific Diagram

Flat Slot Die Coater With Heatable Vacuum Chunk100mm Width 120oc Max - Msk-afa-pd100

Slot Die Coating Rheology - Expert Analyses From The Rheology Lab

Flat Slot Die Coater With Heatable Vacuum Chunk100mm Width 120oc Max - Msk-afa-pd100

Slot-die Coating Theory Design Applications Ossila

Pdf A Review Of The Operating Limits In Slot Die Coating Processes

Blade Coating And Slot-die Coating Ab Schematic Illustration Of Download Scientific Diagram

Slot Die Coating Head Design Peatix